Zhongbao Flange-Escort For Your Project

Stainless steel pipe cap

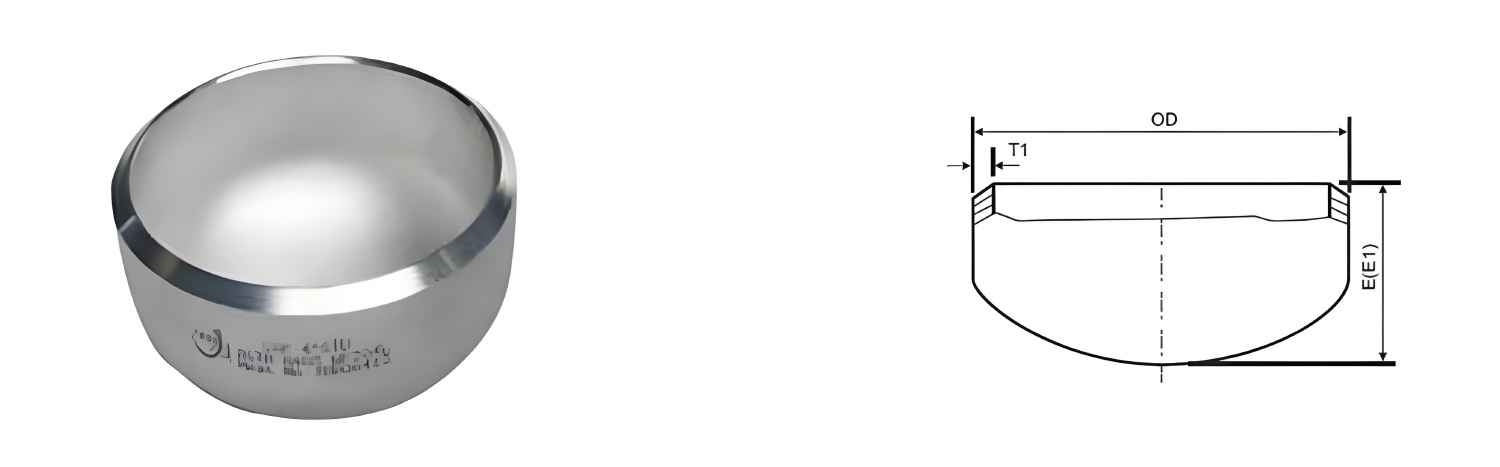

- Commodity name: Stainless steel pipe cap

Contact Info

Classification

Product Details

Pipe caps, pipe caps, also known as heads, plugs, pipe caps, pipe covers, mufflers, are welded to the end of the pipe or installed on the external thread at the end of the pipe to cover the pipe plug fittings. Used to close the pipeline, its function is the same as the pipe plug.

The form of the blind plate is closed, but the blind plate is a removable plug, and the welded cap is not removable. The tube cap includes convex cap, cone shell, reducer segment, flat cap and tight design.

Commonly used materials, stainless steel: 304 304L 316 316L 321 2520 310, 317 and other materials.

Diameter: DN15-DN1200

Wall thickness: SCH5-SCH160

标准:ASME DIN JIS BS GB/T JB SH HG,如下:GB/T12459-2017、GB/T13401-2017、ASME B16.9、SH3408、SH3409、HG/T21635、DL/T695、SY/T0510、DIN2617

Application: water, beverage, beer, food, petrochemical, nuclear power, machinery, medical equipment, chemical fertilizer, shipbuilding, waterproof treatment, pipeline, etc.

Avoid splicing at the r of the dished cap, which will thin and generate high stress.

The welding direction of splicing is only allowed to be radial and circumferential. In the future, large-cap stocks may remove this requirement. The splice distance should be required to be greater than 3δ and not less than 100mm (the welding heat affected zone is a high stress area, and the chemical composition of this area will burn. Therefore, the high stress area should be avoided, which is related to the thickness. According to practical experience, the stress attenuation length is greater than 3δ and not less than 100mm). However, refrigeration equipment is difficult to meet this requirement, and has its own particularity.

Avoid splicing at the r of the dished cap, which will thin and generate high stress.

The welding direction of splicing is only allowed to be radial and circumferential. In the future, large-cap stocks may remove this requirement. The splice distance should be required to be greater than 3δ and not less than 100mm (the welding heat affected zone is a high stress area, and the chemical composition of this area will burn. Therefore, the high stress area should be avoided, which is related to the thickness. According to practical experience, the stress attenuation length is greater than 3δ and not less than 100mm). However, refrigeration equipment is difficult to meet this requirement, and has its own particularity.

Technical parameters

| Nominal diameter | End outer diameter | Distance from back face to end face | ||||

| DN | NPS | Series A | Series B | E | Ultimate thickness T at length E | E1 |

| 15 | 1/2 | 21.3 | 18 | 25 | 4.57 | 25 |

| 20 | 3/4 | 26.9 | 25 | 25 | 3.81 | 25 |

| 25 | 1 | 33.7 | 32 | 38 | 4.57 | 38 |

| 32 | 1.1/4 | 42.4 | 38 | 38 | 4.83 | 38 |

| 40 | 1.1/2 | 48.3 | 45 | 38 | 5.08 | 38 |

| 50 | 2 | 60.3 | 57 | 38 | 5.59 | 44 |

| 65 | 2.1/2 | 76.1(73) | 76 | 38 | 7.11 | 51 |

| 80 | 3 | 88.9 | 89 | 51 | 7.62 | 64 |

| 90 | 3.1/2 | 101.6 | 64 | 8.13 | 76 | |

| 100 | 4 | 114.3 | 108 | 64 | 8.64 | 76 |

| 125 | 5 | 139.7 | 133 | 76 | 9.65 | 89 |

| 150 | 6 | 168.3 | 159 | 89 | 10.92 | 102 |

| 200 | 8 | 219.1 | 219 | 102 | 12.7 | 127 |

| 250 | 10 | 273 | 273 | 127 | 12.7 | 152 |

| 300 | 12 | 323.9 | 325 | 152 | 12.7 | 178 |

| 350 | 14 | 355.6 | 377 | 165 | 12.7 | 191 |

| 400 | 16 | 406.4 | 426 | 178 | 12.7 | 203 |

| 450 | 18 | 457.2 | 478 | 203 | 12.7 | 229 |

| 500 | 20 | 508 | 529 | 229 | 12.7 | 254 |

| 550 | 22 | 559 | 254 | 12.7 | 254 | |

| 600 | 24 | 610 | 630 | 267 | 12.7 | 305 |

| 650 | 26 | 660 | 267 | 1 | 1 | |

| 700 | 28 | 711 | 720 | 267 | 1 | |

| 750 | 30 | 762 | 267 | 1 | ||

| 800 | 32 | 813 | 820 | 267 | ||

| 850 | 34 | 864 | 267 | 1 | ||

| 900 | 36 | 914 | 920 | 267 | 1 | |

| 950 | 38 | 965 | 305 | 1 | ||

| 1000 | 40 | 1016 | 1020 | 305 | ||

| 1050 | 42 | 1067 | 305 | |||

| 1100 | 44 | 1118 | 1120 | 343 | ||

| 1150 | 46 | 1168 | 343 | |||

| 1200 | 48 | 1220 | 1220 | 343 | ||

| Note: Height E is applicable when T does not exceed the value in brackets, otherwise E1 height should be used. | ||||||

Keywords

Get More Product Information For Free

Note: Please leave your contact information and our professionals will contact you as soon as possible!

Recommend Products